Guidelines for selecting gases used in Plasma cutting techniques

Plasma cutting technique is relatively new method and is being used more and more in our country due to the advantages of convenience as well as the quality and aesthetics of the cutting. The gases used in plasma cutting have their own advantages and disadvantages when cutting different metal materials such as steel, stainless steel or aluminum.

The commonly used gases in Plasma cutting include: Air to be cleaned, Argon - hydrogen mixtures, nitrogen or oxygen.

Guidelines for selecting gases used in Plasma cutting techniques

1. Using air to cut Plasma:

Because of its ability to provide good cutting speeds and quality cuts for carbon steel, stainless steel and aluminum, air is used quite commonly in Plasma cutting. On the other hand, the purified air is also lower cost than other gases. Note that before use, the air needs to be cleaned, remove all dirt and steam. When choosing air, you need to choose the pneumatic and filtration system that suits the cutting job requirements.

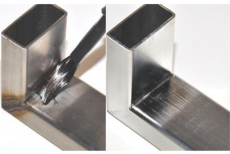

One of the problems with air cutting is its effect on the welding of plasma cutting areas because the cutting area is often oxidized or oxidized. The solution is to use a solder wire containing deoxidizing agents or nitrogen.

Compared with the above small limitation, with the advantages such as cheap price, less slag, high cutting speed, less impact on equipment life, air is the best choice for Plasma cutting work in small workshops.

2. Using oxygen to cut Plasma:

Because of the best cutting speed and the best quality of cuts, this is the first choice in mills when cutting carbon steel. Oxygen will work with carbon to reduce the melting point due to the oxide creating smoother cuts due to the small particle size.

Disadvantages of using oxygen to cut plasma are quite expensive as well as low equipment life but offset the quality of good cutting.

3. Using nitrogen gas to cut Plasma:

Is the oldest method used and is still very popular when cutting aluminum or stainless steel for cutting lines with high quality and low equipment consumption. However, it is not really optimal when cutting aluminum sheets over 0.5 inch thick using Argon + hydrogen.

Typically air is used as protective gas. If CO2 protection gas is used, the quality and cutting speed can be improved. When cutting Plasma nitrogen can use water to cut, especially when cutting aluminum or stainless steel helps smooth cutting lines. However, this method is costly in equipment and operating costs.

4. Using Argon + Hidro to cut Plasma

When cutting aluminum or stainless steel above 0.5 inch it is best to use a mixture of 65% Argon + 35% Hidro. This gas mixture provides the highest temperature for plasma cutting, giving smooth cuts when applied on stainless steel. Nitrogen is often used as a protective gas in this case. However, this method costs a lot of equipment and operation costs.