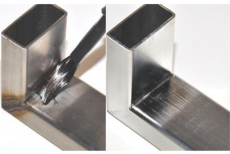

Beautiful welding

Good welding is required welds with even height, less slag

So how to solder a good solder and quality as shown on the picture?

1. Choose the appropriate type of welding rod, reasonable size

Choosing the right size rod is the first element to be soldered. The type of welding rod should be suitable for welding materials, type of cover, etc. To select the appropriate welding rod based on welding materials, consult the manufacturer of welding materials, suppliers. device…

Depending on the thickness of the welding, we use different types of welding rod size.

2. Set the welding current properly

Depending on the type of electrodes used, the device must be set to positive, reversing or alternating current. Make sure you have the correct settings before welding.

Weld failure due to too high welding currents. Wide, flat and discontinuous welds

Weld failure due to low welding currents. High welds, not glazed

3. The arc length is reasonable

Basically the welding arc length should be relative to the welding rod diameter, should not exceed the welding rod diameter

When the arc length is too short can cause unstable arc, can turn off the arc, the welding hardened faster and create high welding scales.

The note to create beautiful welds

Too much caustics will cause splashes, slow deposition rates and porosity.

The note to create beautiful welds

4. Adjust the welding speed and angle of the welding rod properly

Moving rods too fast to make the welded faults become undulating, broken, metal slag, splashing

Too slow welding will produce welded and non-weldable scales. The heat lost can not melt the solder.

The note to create beautiful welds

Hope the things we just shared can help the welder know how to make a reasonable welding to create beautiful welding, quality assurance effective in the work process.